Proud to offer over twenty five years of outstanding services and operations.

Accurate Brazing is a full-service vacuum brazing and heat treating enterprise with almost 40 years in the business. Over that time, we’ve become adept at heat treating materials that include stainless steel, super alloys, copper, and refractory materials. Unlike competitors, Accurate Brazing has the unique expertise, capacity and equipment to take new programs and get them into production quickly.

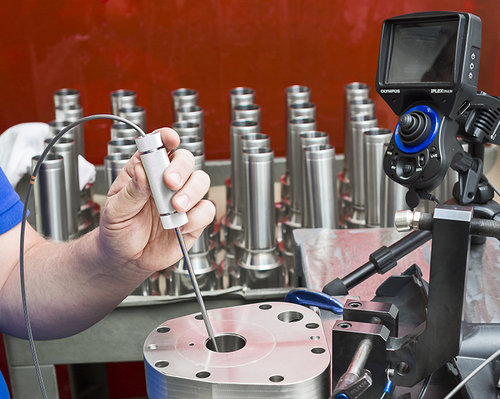

Specialties include end-cover, nozzle and cartridge assemblies for fuel delivery systems. We also process heat exchangers, tube assemblies, medical implants, consumable welding products, and semiconductor equipment. We braze and/or heat treat various materials including: Stainless steel (300 and 400 series), “Super Alloys” (Inconel, A286, Rene 41, Waspalloy, Hastalloy, etc.), copper, refractory materials (Moly, Titanium, Tungsten and carbon steels).

We have also had great success heating treating A, D and M series tool steels. Vacuum heat treating allows for uniform heating and cooling which minimizes distortion and provides excellent metallurgical properties.

Sign up with your email address to receive more information, news or updates. We respect your privacy.

"*" indicates required fields